ePattern

ePattern

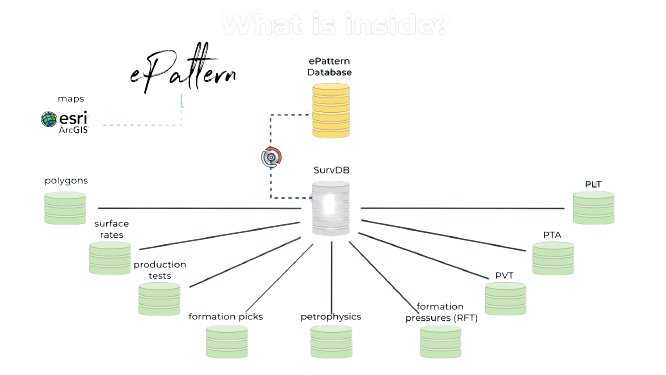

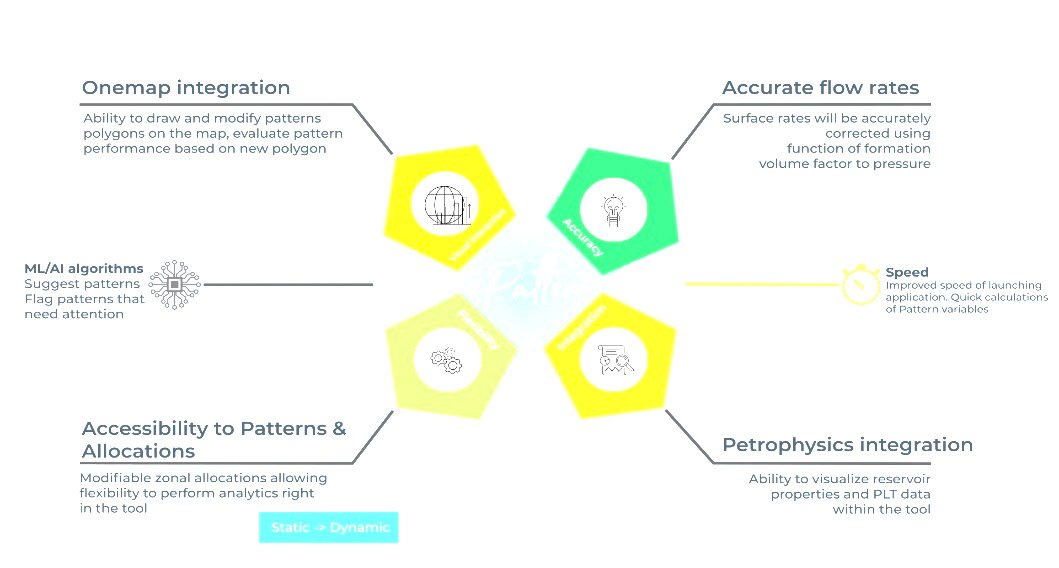

Analytical software combines cutting-edge digital technologies as well as industry know-how in order to simplify and assist engineers in both their day-to-day tasks as well as strategically important decisions. Using Cloud based technologies with state-of-the-art ML techniques, ePattern is web-based pattern management that allows:

- engineers to extract most of their data and see beyond simple visualization techniques

- multi-disciplinary teams to access and evaluate Pattern Health`s across the area

- to perform detailed analysis of key diagnostic parameters

- to compare KPI`s against targets and flag deviations predefined scope

ePattern helps to analyze oil and gas parameters pertaining to drilling and production operations as well as the visualization of wells and completions.

By applying ML techniques, software allows engineers to extract more value from data and streamline analysis/decision workflows.

Streamlining analysis/decision making workflow allows engineers to reduce spent time without any reduction in quality of decision making. ML techniques additionally allow engineers to further increase the quality of their decision making by providing data/relationship that were not visible beforehand.

Due to the nature of the ePattern toolkit, it could be used anywhere that data-driven analysis is required. With the modular nature of ePattern, usage in a new field of interest could be as easy as switching up the core visualization package and adding custom-made ML and calculation modules tailored specifically for those specific fields. Due to the cloud nature of the toolkit, no change in infrastructure is required. ePattern could be used in any field that is data-driven and has an existing database.

About

Built for modern directional programs, the product combines robust metallurgy with a purpose-built geometry that balances strength, flexibility, and toolface control. It’s compatible with standard BHA components and common rig workflows, minimizing integration risk and non-productive time during installation.

Application

- High-angle wells and extended-reach laterals

- Intervals with ledging, washouts, or variable hole quality

- Curves requiring precise toolface control

- Formations prone to stick-slip, whirl, or torsional instability

- Sections where torque/drag is approaching limits

Methodology

- Pre-job engineering: Define target sections, expected doglegs, WOB/TOB windows, and BHA placement.

- BHA integration: Place the tool at recommended spacing relative to the bit, motor/MWD/LWD, and stabilizers to optimize contact distribution.

- Parameter set-up: Start with planned WOB, RPM, flow, and ROP; monitor torque/drag trends and adjust as required.

- Real-time optimization: Use surface data to keep toolface steady, mitigate stick-slip, and maintain a consistent penetration regime.

- Post-run review: Compare torque/drag charts, vibration logs, and ROP vs. offset wells to lock in the best recipe for subsequent runs.

Benefits

- Higher ROP & footage per run: Reduces frictional losses and stick-slip to keep the bit cutting efficiently.

- Improved steerability: Aids toolface stability for cleaner curves and lateral holds.

- Lower torque & drag: Smoother movement through ledges, tight spots, and build/hold sections.

- Fewer reamer trips: Helps navigate doglegs and micro-restrictions, cutting flat-time.

- BHA protection: Distributes loads to reduce shock/vibration and component wear.

- Operational flexibility: Works across varied mud systems, hole sizes, and lithologies.